Eco-friendly composite doors

Green Doors, now available in all colours

We’ve always been ahead when it comes to taking responsibility for the planet.

From day one we chose to use a calcium zinc-based compound in the extrusion of the door frame (which we make in different lengths to avoid waste) because it’s much kinder to the planet than lead-based additives.

The door’s inner rigid foam system is completely, utterly, one hundred percent CFC-free.

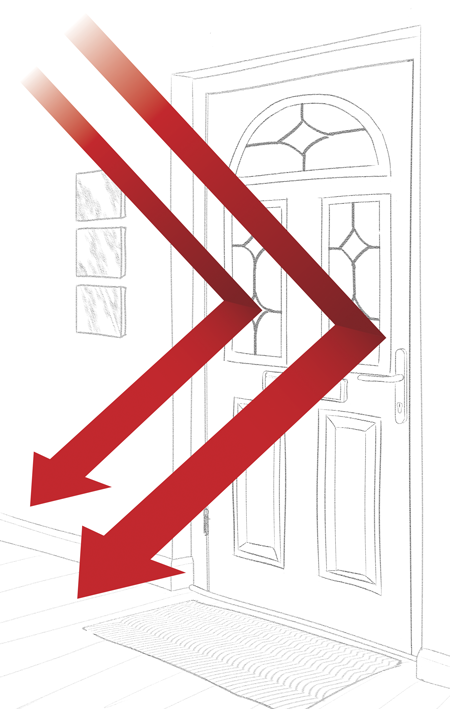

Energy-efficient doors

All of Door-Stop’s doors exceed the current Building Regulations for energy efficiency, which came into force in October 2010, covering front doors for the first time. Under the legislation, all new doors sold and fitted in England and Wales must have a U-value of 1.8W/m2K (1.6W/m2K in Scotland) or less. The door’s U-value is a measure of its energy efficiency, and the lower the U-value, the more energy-efficient the door.

Choosing thermal glass on Door-Stop doors makes them even more energy-efficient, with an ultimate U-value of just 1.1 W/m2K.

Many manufacturers of doors made of timber, aluminum or PVC panels may struggle to meet the 1.8W/m2K requirement and many do not provide proof.

GRP - the longest product lifespan

| Door type | Expected life | Maintenance |

|---|---|---|

| Softwood Door | 25 Years | Paint, 5 Years |

| Hardwood Door | 35 Years | Paint, 5 Years |

| Steel Composite Door | 30 Years | Wipe Clean |

| PVC Composite Door | 25 Years | Wipe Clean |

| GRP Composite Door | 35 Years | Wipe Clean |

| PVC Panel Door | 20 Years | Wipe Clean |

Information from HAPM (Housing Association Provident Mutual) and BRE (Building Research Establishment)

Carbon Footprint

And we’ve taken big steps to reduce our own carbon footprint too. Door-Stop doors are made right here in the UK, unlike the products of other door companies. And we carefully plan and all our delivery routes to cut down the amount of fuel we use.

Other manufacturers look at our doors and go green with envy - we’re just greener.